Production

The garment production process in the clothing industry is one of the elements with the most significant environmental impact. We treat the order planning process of our suppliers with all the more care.

We control the production process

We match production levels to the supply generated by our customers. This is achieved with the use of cutting-edge technology developed by our team of IT experts who, using data science, machine learning and mathematical algorithms, are able to forecast the level of demand for our collections. This, in turn, allows us to reduce the amount of clothing ordered from our suppliers and minimise the share of unsold collections.

We support our suppliers

In parallel, we pursue a programme to support our suppliers in implementing best practices that reduce the use of natural resources in the garment production process. We gradually increase our portfolio of partners who use environmentally friendly technologies that reduce water and energy consumption in garment manufacturing.

Safe production

We are also committed to the effective elimination of hazardous chemicals from the industry; hence, in 2020 we became the first Polish company to be awarded the status of a uzyskaliśmy status of a Friend of Zero Discharge of Hazardous Chemicals (ZDHC).

It is an international initiative that aims to globally reduce the chemical footprint generated by the apparel industry and eliminate hazardous substances from the textile industry.

We have been involved in the adoption of the ZDHC MRSL (Manufacturing Restricted Substances List). It is a list of banned, hazardous substances that is constantly updated by the organization.

We prefer to cooperate with responsible and climate-conscious factories. It is to them that we outsource larger production batches, which automatically becomes a motivating factor for the sewing plants to join the ZDHC initiative.

This way, we encourage local entrepreneurs to adhere to chemical safety in production, engage in responsible chemical management and proper disposal of waste such as wastewater and post-production water.

The ZDHC member factories we cooperate with are obliged not only to commit to water treatment, but also to improving its quality enough with a view to gradually restoring the aquatic ecosystem. To this end, the sewing plants are obliged to periodically submit their post-production water for physical and biochemical testing.

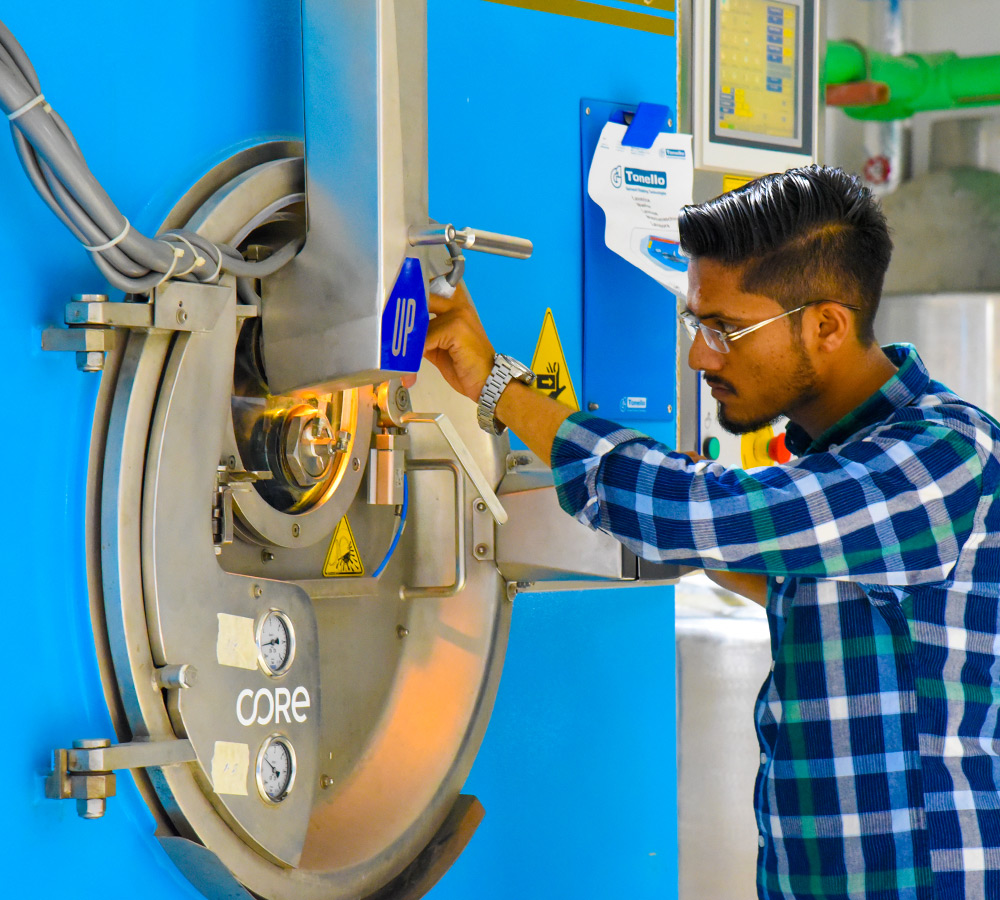

Jeanologia®

In the portfolio of factories producing jeans ordered by us, we are gradually increasing the proportion of those that have been accredited by Jeanologia®, i.e. use patented modern technological solutions to reduce the use of water, chemicals and energy in the production and finishing of denim products.

Quality Guidebook

Irrespective of the ZDHC affiliation, LPP attaches a developed quality standard, the so-called “LPP Quality Guidebook”, to every order sent to the factory.

It contains a detailed list of chemicals banned in the production of the Polish company’s collections and a list of permissible concentrations of other substances compatible with the EU requirements laid down in REACH2.

Improve safety and working conditions

Monitoring the working conditions that prevail among our suppliers is an integral part of our operations.

In 2023, we joined the signatories of the International Accord Pakistan as the only Polish apparel company to do so.

The International Accord is an agreement operating on behalf of the fashion industry to improve working conditions in Bangladesh and Pakistan. Its aim is to collectively act with trade unions to ensure safety in factories. Please take the time to read the summary of the past decade of our actions, including initiatives implemented in the facilities of our suppliers in Bangladesh, achieved in collaboration with the Accord.

We regularly subject the factories to external audits, but also to inspections carried out by our auditors permanently based in our Dhaka office. We verify the level of safety of the sewing plant buildings’ construction, electrical solutions, and fire protection.

In 2023, we were the only Polish apparel company to join the ranks of the International Accord Pakistan signatories in an effort to improve safety and working conditions in garment factories in Pakistan.

Additionally, in 2022 we joined amfori BSCI – an international association striving for more transparent and sustainable trade.

Through it, we carry out detailed monitoring of factories we collaborate with or are planning such collaboration. In this way, we eliminate from our environment those factories that do not provide their employees with decent working and living conditions.

The amfori BSCI Code of Conduct covers 13 areas, including occupational health and safety, prohibition of child labour, prohibition of forced labour, and the right to the freedom of association.

LPP Code of Conduct

Collaboration is only initiated with those factories that have committed to comply with our “LPP Code of Conduct” – a document that sets out our requirements taking into account the provisions of the International Labour Organisation conventions and the Universal Declaration of Human Rights, as well as committing suppliers to absolute care for the environment.

The rules it contains cover such areas as:

• the need to have an appropriate remuneration policy and formal conditions of employment for employees,

• an absolute ban on the employment of children,

• voluntary work,

• freedom of association,

• equal treatment of all employees,

• health and safety standards.

Discover our reports

Here you will find our latest report and all previous publications. Check LPP's progress, learn about environmental, social and business results.